In today’s accelerating world economy, manufacturing enterprises are faced with the market realities of ever more demanding customers, steeping price erosion, and shrinking product life cycles. The digital transformation in supply chain management has made industries follow a rigid drive to cut costs and focus on core competencies constantly. The use of advanced technologies such as AI and Analytics in the supply chain sector help businesses understand the complex data but they are still lacking in post implementation maintenance. Not only this, over 30% of the supply chain management businesses believe in outsourcing some or all of their technical capabilities. Why is this happening?

Why are manufacturing and supply chain businesses highly reliable on technical outsourcing and strategic procurement when it comes to meeting customers’ demands?

There’s one answer to justify the above questions.

Supply chain and similar manufacturing enterprises need to manage close relationships with a large number of supply bases on a real-time basis. This is not just an advancement but a necessity to survive in a highly competitive market. That’s when Supplier relationship management (SRM) software comes into play.

Introducing the concept of supplier relationship management (SRM) to business

Suppliers are an integral part of the supply chain management process. If the suppliers are not monitored closely, the business harm could be up to any extent. You can suffer a delayed product launch, damaged brand image, penalties by regulatory authorities, and more.

To overcome such risks, supply chain enterprises and similar businesses follow the SRM system.

Supplier relationship management is a systematic approach to evaluate suppliers (or vendors) that supply goods, services, and materials to an organization, determine their contribution in the supply chain process, and develop a strategy to improve their performance. This concept applies to manufacturing industries and every enterprise that regularly deals with suppliers, especially in areas of operations and project management.

This may become a challenging task but not when businesses have SRM software to rely on.

What is SRM software?

An SRM software centralizes supplier-related data, helps update the fitting suppliers, analyzes their performance, and detects related risks to improve supply collaboration, planning, and management.

When we talk about the importance of the SRM system in supply chain and b2b businesses, there are two essential pillars to recognize

- Evaluate if the suppliers are performing as per the organizational needs

- Identifying areas of improvement while engaging with suppliers throughout their lifecycle

The above two factors primarily exhibit why businesses need a supplier relationship management system. Apart from these, srm management gets businesses most of the supplier’s service. With constant evaluation, communication and feedback, it’s much easier to work closely with the suppliers and generate quick solutions.

While we are talking about what the SRM system does, we also need to get familiar with how it does it. The SRM software system is packed with tons of tools and features that industries can leverage to yield successful results.

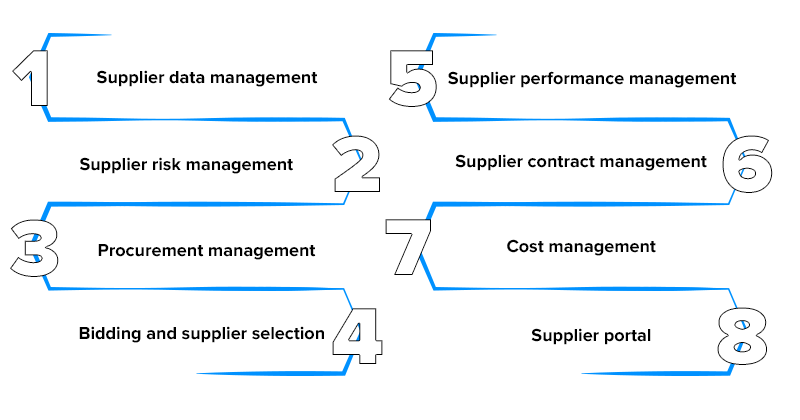

Core features and use cases of the SRM business software

1. Supplier data management

This involves features such as

- Document storage (transactions, business receipts, invoices, contracts with suppliers, certifications of suppliers with background checks, documents of suppliers’ compliance, etc.)

- Registration of suppliers and sub-suppliers, and contractors by self-registration or sourcing via supplier portal

- Automatic linking of the supported data record of all suppliers (for instance- all the background data, work history, and projects of a supplier are available on the supplier’s profile)

- Personal notifications on updates in supplier’s data or document

- Storage and tracking of all supplier data (current capacity and pricing, allotted location, ongoing operations, and previous company, etc.)

2. Supplier risk management

This involves features such as

- Real-time supplier risk mitigation and monitoring (financial and operational risks from the public/private data sources detected by Artificial Intelligence).

- Automatic risk alerting (on any operational risk exposure)

- Detailed dashboard (with an overview of overall risks involved, per risk factor, the possibility of risk as per supplier’s data, etc.)

- Current supplier compliance regulatory check

3. Procurement management

This includes features such as

- Quick doc based creation of purchase requisitions and orders

- Creation and management of allotted suppliers list (for instance- supplier assignment by project specialist to a specific service or location based on data insights)

- Supplier status tracking for purchase orders and requisitions

- Tracking of execution order (can be done for multiple tiers and sources)

- Automated three-way matching process (order receipts, purchase orders, and suppliers invoice). This is done to avoid any inconsistencies.

- Communication tools to discuss orders with specialists and suppliers

4. Bidding and supplier selection

This includes features such as

- AI-based status pre-qualification tools (for assessing financial stability, risk of supply disruptions, regulatory compliance, etc.)

- Automated sourcing event approval workflow

- Supported collaboration with department managers on supplier nomination and selection

- Setup of supplier compliance requirements (capacity, sustainability, delivery terms, quality standards, etc.)

- Form-based creation of events, auctions, and tenders

- Supplier bid comparison

5. Supplier performance management

This includes features such as

- Accessible dashboards with a supplier activity overview

- Automated alerts on disrupting supplier performance

- Supplier segmentation (based on engagement level and performance)

6. Supplier contract management

This involves features such as

- contract status tracking

- Automated contract renewal

- Template-based creation of supplier’s contract

7. Cost management

This includes features such as

- Cost limits setups (per supplier/department)

- Real-time spend analysis

8. Supplier portal

This involves features like

- Supplier catalog editing and updating

- Supplier forum with Q/A sections and files

- Template-based and custom supplier surveys creation (for suppliers feedback)

The above supplier relationship management software features are more than enough to manage the entire supplier base chain and fulfill the organizational needs. But the applicability of the SRM system doesn’t end here. Enterprises are well aware of the supremacy of custom software development but they often neglect the importance of post-deployment practices that could save them from a number of challenges.

Enterprises need to strategize the implementation of the SRM system in their business. Even after you seek software development services, one factor you must always focus on is the supplier relationship management strategies.